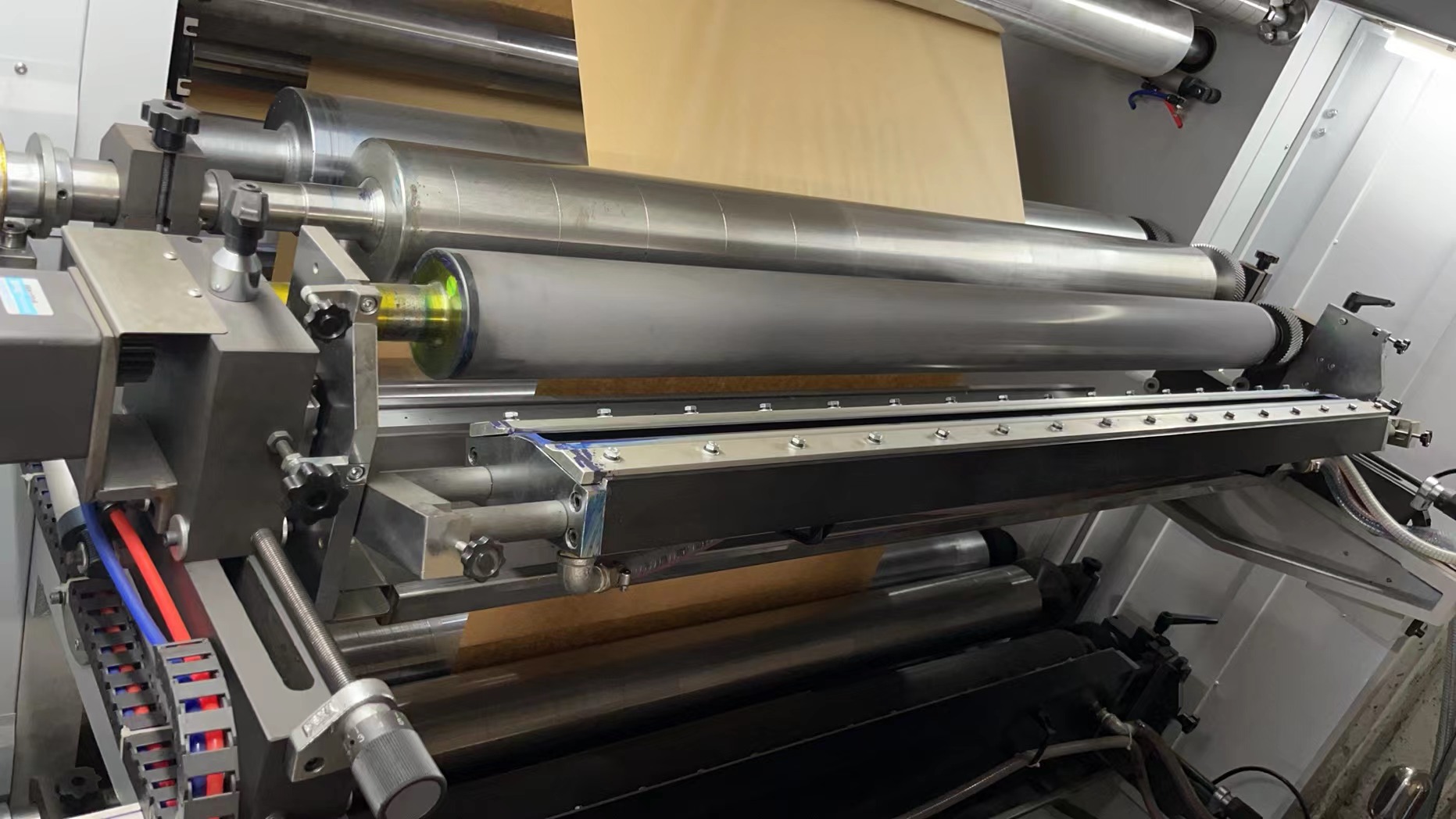

Wide Web Paper Bag Flexographic Printing Machine

Feature:

1) Single work station

2) Hydraulic clamp,hydraulic lift the material , hydrauliccontrol the unwinding material width,it can adjust left and right movement.

3) Magnetic powder brake auto tension control

4) Auto web guide

5) Pneumatic lifting and lowing printing plate cylinders auto lifting plate cylinder when the machine is stopped. After that can run ink automatically. When the machine is opening,it will make alarm to start the auto lowering plate printing cylinder.

6) Inking with ceramic anilox chambered doctor blade ,ink pump circulation

7) High precision planetary gear oven 360°circulation longitudinal register

8) ±0.20mm transverse register

9) Adjust inking press and printing pressure press by manual

10) Adopt with external heating pipe, temperature display, electric current control,centrifugal blower bring the wind

6) Inking with ceramic anilox chambered doctor blade ,ink pump circulation

7) High precision planetary gear oven 360°circulation longitudinal register

8) ±0.20mm transverse register

9) Adjust inking press and printing pressure press by manual

10) Adopt with external heating pipe, temperature display, electric current control,centrifugal blower bring the wind

11) The machine adopt with synchronous belt drive and hard gear face gear box. The gear box adopt with

synchronous belt drive each printing group high precision planetary gear oven(360 º adjust the plate) gear driving the press printing roller

synchronous belt drive each printing group high precision planetary gear oven(360 º adjust the plate) gear driving the press printing roller

12) After printing, long running material space ,it can make the ink drying easily,better results

Product Made from Machine:

Teachnical Specifications:

Teachnical Specifications:

| Max. Web Width | 1200mm |

| Max. Printing Width | 1160mm |

| Printing length range | 230-1000m |

| Printing Speed | 5-100m/min |

| Color | 2~6 |

| Register precision | ≤±0.20mm |

| Max. Unwinding diameter | 1300MM |

| Max. Rewinding diameter | 1300MM |

| Thickness of plate(including the thickness of double sides glue) | 2.28mm+0.38mm |

| Main Motor Capacity | 21kw |

| Main Power | 380V/AC 3 phase 50HZ |

| Overall Dimension(LxWxH) | 8200x2250x2500mm |

| Machine Weight | 6100kg |

*lts overall dimension and manufacturing Process are subject to change without further notice.

Detail Configuration:

| Name | Origin |

| Main motor | China |

| Inverter | Inovance |

| Rewinding motor | China |

| Rewinding Inverter | China |

| Inking reducer | China |

| All of the low voltage control switch | Germany |

| Main bearing | Taiwan |

| Roller bearing | China |

| PLC Touch screen | Omorom |